5 keys to understanding the French reparability index

Extending the life of products is becoming a major issue. Faced with the impact of our consumer society and the new behaviours of buyers, public policies are looking for solutions. Introduced into the Consumer Code in January 2021 via the AGEC Act, the Repairability Index is a new mandatory regulatory measure for 8 product families. A new pictogram will be displayed on the product families concerned to provide consumers with better information.

What is the aim of the French reparability index?

The reparability index has a dual objective. On the one hand, it provides consumers with clear information on the repairability of products to help them make responsible purchasing decisions. On the other hand, it encourages eco-design by encouraging manufacturers to put more repairable products on the market while improving their repair support policies, thereby promoting healthy competition. However, care must be taken: a product that is not very repairable (with a poor index) may be a very reliable product, and conversely, a product that is very repairable (with a good index) may be an unreliable product.

This is where the difficulty lies in assessing durability and not just reparability.

Which products are covered by the Repairability Index?

8 product families are covered by the French government’s reparability index. You will find the index pictogram on the following categories:

- washing machine (porthole, top)

- dishwasher

- hoovers (corded, cordless and robot)

- Smartphones

- laptop computer

- televisions

- electric lawnmowers (corded, battery, robot)

- high-pressure cleaner

A European reparability index is currently being developed for smartphones. It is regrettable that these two indices are not based on the same calculation method, but in time the European index should take precedence.

What does the reparability index look like?

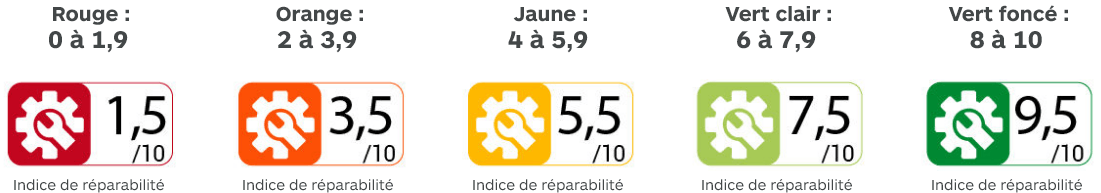

The Repairability Index consists of a pictogram, a score and an associated color code:

How the reparability index works:

The French reparability index uses a rating scale of 1 to 10, where 10 indicates very easy reparability and 1 indicates very difficult reparability.

It assesses the ease with which a product can be restored in the event of a breakdown or malfunction, and this assessment is carried out by the manufacturer itself using specific calculation grids for the 8 product categories covered by the index.

The 5 rating criteria of the French Repairability Index:

1st Criterion: Technical documentation

This criterion assesses the completeness, timeliness and accessibility of technical documentation to stakeholders, including repairers and consumers. It examines the presence of disassembly diagrams, exploded views, wiring diagrams, electronic board diagrams, repair instruction manuals, error codes and diagnostics, as well as operating and maintenance manuals.

2nd Criterion: Demonstrability

In this criterion, the emphasis is on the ease with which important parts can be dismantled (breakage, breakdown) and replaced without damaging other components. The points examined include ease of dismantling, the tools required and the type of fasteners.

3rd Criterion: Availability of spare parts

This criterion examines the producer’s commitment to supplying essential parts after production of the product has been completed. It also assesses the delivery times associated with the supply of these spare parts, whether to the after-sales service or to the end user.

4th Criterion: Price of spare parts

This criterion focuses on the price of spare parts, a simple but essential aspect to consider.

5th Criterion: Specific criterion

This criterion is specific to each product category and is linked to the assessment of reparability. For example, in the case of a washing machine, this could be the accessibility of the usage meter.

Who calculates the reparability index?

In France, the reparability index is self-reporting, meaning that the calculation is carried out by the producers themselves, in accordance with the calculation matrices provided by the French government. This is one of the limitations of this tool, and Répression des Fraudes has recently pointed out several shortcomings.

The DGCCRF (Direction Générale de la Concurrence, de la Consommation et de la Répression des Fraudes – Directorate-General for Competition, Consumer Affairs and Fraud Control) carried out a massive control campaign of the reparability index, and the first returns were made at the beginning of 2024:

- 529 companies were audited

- In more than 60% of cases, anomalies were found

- In more than 30% of cases, the score is not displayed in accordance with the rules, even though this is compulsory

- Many professionals do not provide the calculation grid used to obtain the score, which is an obligation

It should be emphasised that manufacturers are required to make available the information used to determine their indexes, so that anyone can check their accuracy. In some cases, manufacturers use independent third parties to calculate or verify the index to ensure greater impartiality.

Enhance Your Product’s Durability with Repair-Ability

Repair-Ability is a powerful tool designed for professionals to optimize the durability of their products. It offers detailed insights and recommendations to improve repairability scores, helping manufacturers extend product lifecycles and meet sustainability standards. With Repair-Ability, you can streamline product design improvements and boost durability performance.