Assessing a product’s reparability

Repairability is a subject that is widely addressed by players, and an easy entry point to the theme of sustainability. We decided to create tools for all players wishing to improve the repairability of their products, across all categories, based on standardised European assessment approaches.

Why assess the reparability of products?

In the design or redesign phase, it is essential to consider and clearly define a repairability strategy in the same way as a reliability strategy, in order to bring truly sustainable products to market.

Repairability and eco-design strategy

Repairability is an excellent part of an eco-design strategy, as it is an effective lever for extending the useful life of electrical appliances, for example. By helping to extend useful life, repairability contributes to the amortisation of the results of impact category indicators linked to all phases of production, upstream of use;

Repairability and Obsolescence

Challenging the reparability of its products is also an excellent way of guarding against the risk of premature obsolescence. The communication costs for a manufacturer are very high, and it is essential to check that the various repair scenarios are consistent with the risks of identified failures;

Calculate your score reparability

Improve the reparability of its products using a standardised methodology

Our team of experts has developed a scoring tool that complies point by point with standard 45554. We support you in understanding the criteria and evaluating them, culminating in a report including a reparability score.

The advantages of the reparability score by LONGTIME® are

- Weighting of criteria and priority areas for a more accurate assessment

- Evaluation of 14 criteria, some of which are “exclusionary”, for in-depth analysis

- Generic tool adaptable to all product families

- Third-party verification for greater transparency

- Anticipate the European reparability index based on this standard

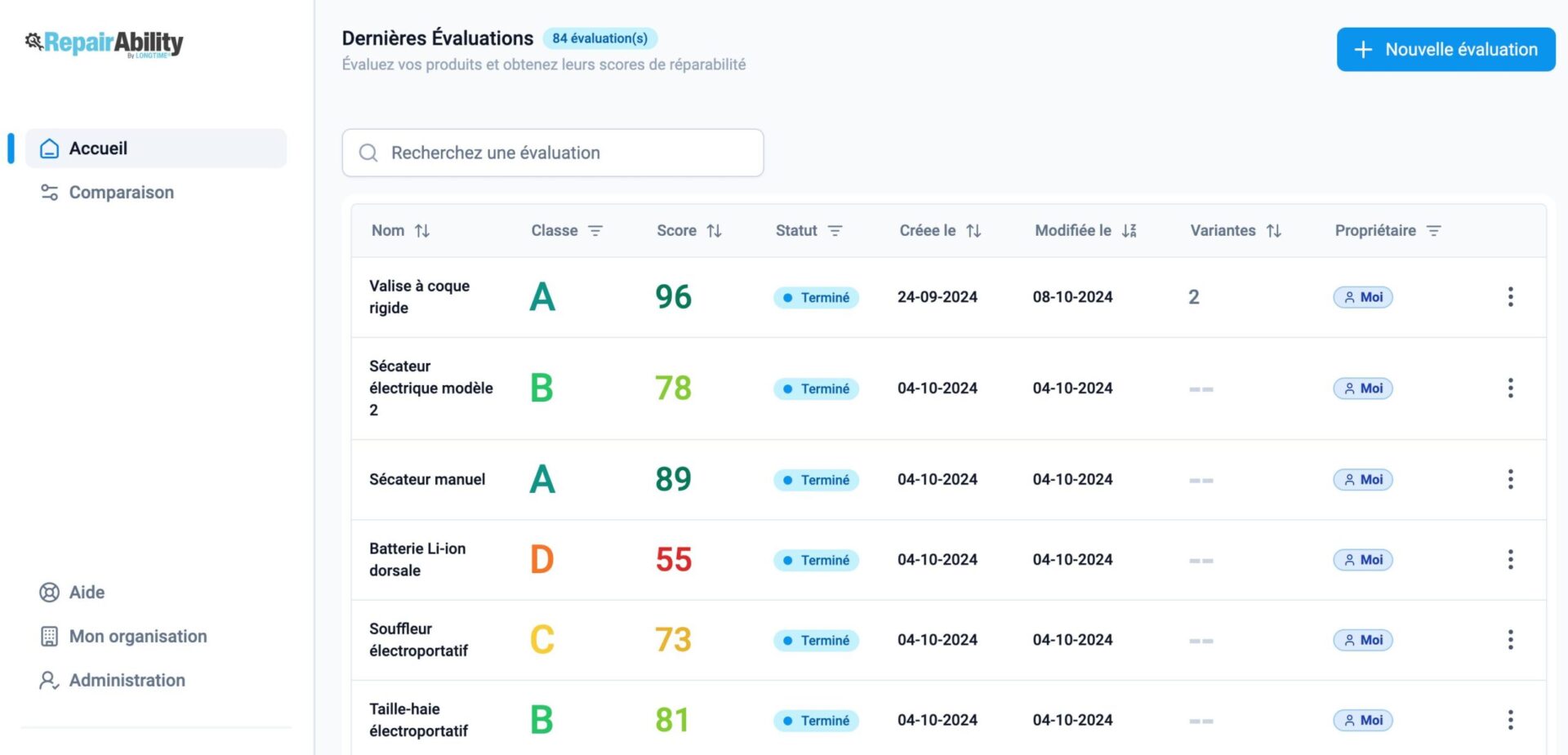

Software for assessing product reparability

Repair-Ability is the essential tool for professionals wishing to assess and improve the reparability score of their products. Based on the European standard EN 45554, this tool calculates a precise reparability score by analysing various criteria and components of your products. Thanks to a detailed report, including sub-scores, you can easily identify areas for improvement and receive technical and organisational recommendations for optimising reparability. Adaptable to a wide range of products, whether electronics, household appliances or other items, Repair-Ability enables you to anticipate regulatory changes, validate your R&D projects, and strengthen your CSR and CSRD reporting processes. With the option of having your scores audited by a third party, this tool guarantees transparency and credibility with your customers and partners, while ensuring that you comply with the requirements of European directives such as the Green Claims.

Testimonial from a beta tester

“Thank you for this beta test. The time spent on the subject is very reasonable in relation to the deliverable obtained. 23 pages may seem like a lot, but it’s the minimum to lay the foundations and to be complete. I really liked the critical review and the suggestions for improvements to get 90/100.

It seems to me that you can launch the official version!”

Sébastien GOUPIL Quality Manager

Process

reparability :

Support in 4 stages

Step 1

We study your product family and collect the information needed for the calculation.

Step 2

During a workshop, we review all the criteria and find out your product’s initial score.

Step 3

We analyze and review the data in-house, and you receive the full report.

Step 4

If you wish, we can include a new calculation following the implementation of the recommendations.

A full report and guidelines for improvement

The report includes all the data you need to improve the repairability of your products, including :

- objectives for assessing repairability on the target product

- priority parts and their weighting

- evaluation of each criterion and priority area

- initial score out of 100 and associated class

- breakdown of organizational and product scores

- improvement simulations

Training in assessing reparability

Our team has developed a one-day training programme to provide a better understanding of the subject and the associated methodological standard for assessing it.

Qualiopi training

Training objectives :

- Understand the diversity of concepts, issues and methods related to the key notions of repairability of manufactured products,

- Understand the legal framework, current experiments and the ecosystem of players,

- Acquire a turnkey methodology for applying the principles of standard 45554 in a practical and operational way within your organisation,

- Assimilate the principles of methodological standard 44554,

- Build your approach to assessing and improving reparability using a structuring methodology that can be adapted to any type of company or organisation.

Key skills targeted :

- Structure your project to assess and improve reparability based on the NF EN 45554 methodological standard.

- Identify and prioritize priority parts of a product

- Understanding the methodology for assessing reparability

- Understanding reparability assessment criteria

- Identify the priorities specific to your organisation as part of its commitment to reparability

- Assess your organization’s maturity in terms of reparability issues and carry out a self-assessment

questions on reparability

What is product reparability?

Product reparability refers to the ease with which a product can be repaired in the event of a malfunction or breakdown. Repairability means assessing a product’s ability to be repaired according to its own specific failure scenarios.

In quality terms, repairability means restoring the nominal capabilities of a product that has broken down and enabling the transition from a dysfunctional state to a functional state.

It is generally measured by the ability to disassemble, repair and replace product components, and by the availability of spare parts and repair manuals.

What are the advantages of reparability?

1) Reduce premature waste:

Equipment that breaks down is all too often discarded. This is leading to a massive increase in waste volumes, particularly WEEE, which is highly damaging to the environment. Working on the reparability of products is the first step towards respecting the use cycle of appliances and the necessary ecological transition.

2) Reduce pressure on resources :

Product reparability is a key factor in preserving natural resources. Indeed, when products are designed to be easily repairable, they can be reused and their useful life extended rather than being thrown away and replaced by new products.

Reducing the renewal rate of a product has a direct impact on reducing the demand for raw materials, energy and other natural resources needed to produce new products;

3) Reduce costs:

As well as being an ecological act, repairing products is often less expensive than buying a new one. When products are designed to be easily repaired, consumers can save money by repairing faults rather than buying new products…

4) Encouraging sustainability:

Products that are easy to repair tend to be more durable. By encouraging the reparability of products, we can encourage manufacturers to produce quality products that last longer.

5) Promote the circular economy:

The reparability of products is a crucial factor in promoting the circular economy and re-use. Adding value to products or extending their useful life by reusing them almost always requires a refurbishment stage, including maintenance and/or repair operations. Circular economy players such as Envie, Emmaüs and les ateliers du Bocages have every interest in being clear about the repairability of the products they wish to promote.

Lastly, the reparability of products promotes the circular economy at the end of the chain, since end-of-life products have all the characteristics needed to be properly recovered, either through the recovery of spare parts or through the recovery or recycling of raw materials to be used again in the production of new products;

6) Supporting employment :

Repairability can help create jobs in the repair sector. In fact, the more easily products are designed to be repaired, the more work there is for repairers and, more generally, for the repair and re-use industry as a whole.

To sum up,The repairability of equipment is important from both an environmental and a social point of view. From an environmental point of view, repairability is an effective way of combating the production of premature waste, while also reducing pressure on resources. From a social point of view, repairability enables households to preserve and reduce their expenditure, while maintaining a local employment base with low relocation potential via the repair and/or reconditioning sector.

What is the reparability index?

This new regulatory measure will be introduced in France in 2021 as part of the anti-waste law for a circular economy. In practical terms, the reparability index is a score out of 10 designed to quantify the reparability of products. The Agec law introduced this tool into the Consumer Code, and several decrees govern its use.

In concrete terms, the reparability index assesses the ease with which a product can be repaired, based on a number of criteria such as the availability of spare parts, technical documentation, the complexity of the repair, etc. The higher the score, the easier the product is to repair.

What is the purpose of the reparability index?

The purpose of the reparability index is twofold. Firstly, it aims to provide all consumers with clear, legible information on the reparability of the 9 product categories concerned, so that they can make informed decisions when purchasing products.

Secondly, it aims to stimulate the eco-design of products by encouraging manufacturers to design more repairable products while improving their policies to support repair processes such as after-sales service. By rewarding manufacturers who design products that are easier to repair with a higher score, the index encourages healthy competition.

What are the criteria for the reparability index?

A series of criteria must be evaluated to calculate the French government’s reparability index. In detail, here are the criteria for the reparability index.

Criteria 1: Technical documentation

The aim is to assess both the completeness of the technical documentation and its accessibility over time and to the various stakeholders (repairers and consumers).

This criterion verifies, for example, the presence of disassembly diagrams, exploded views, wiring diagrams, electronic board diagrams, repair instruction manuals, error and diagnostic codes, operating and maintenance manuals…

Criterion 2: Demonstrability

In this criterion, particular attention is paid to the dismantling of parts likely to break or break down. Assessing the ease with which defective parts can be replaced without damaging other components is essential. Several points are scrutinized in this criterion, including :

- Parts are easy to disassemble

- Tools for disassembly

- Typology of part fasteners

Criterion 3: Spare parts

Firstly, this criterion verifies the manufacturer’s commitment to ensuring that a number of parts essential to the proper functioning of the product will be available for as long as possible after production has been completed.

It also focuses on the delivery times associated with the supply of these spare parts, either to the after-sales service or to the end user;

Criterion 4: Price of spare parts

This criterion focuses on the price of parts, which is simple but necessary.

Criterion 5: The specific criterion

This criterion is linked to the assessment of reparability, but is specific to each product family. For example, the specific criterion for washing machines is still accessibility for counter use!

How do you calculate the reparability index?

The French reparability index is a rating system expressed on a scale of 1 to 10, where 10 corresponds to a very easily repairable product and 1 to a product that is very difficult to repair. It measures the ease with which a product can be restored to working order in the event of a breakdown or malfunction and communicates this in the form of a display.

The reparability index is self-determined by the producer using calculation grids available for the nine product families covered by the index.

Here are the steps to follow to calculate this index:

1) Identify and understand the measurement criteria of the appropriate calculation grid:

After checking that the product is covered by the French government’s index, the producer must download the grid and understand the scope of its criteria.

2) Assign points for each criterion

The reparability index is based on several criteria:

- accessibility of spare parts (price, availability time and network)

- ease of disassembly (number of steps and tools)

- technical documentation (completeness, network, accessibility)

- a specific criterion, such as software update conditions.

Each criterion is assessed on a scale from 0 to 10. The more the product meets the criterion, the more points it scores.

3) Calculate overall score

Once each criterion has been assessed according to the scale provided in the French government decrees, the overall score is calculated by adding up the points for each criterion and dividing the total by five. A weighting system has recently been introduced to counter certain biases in the calculation matrix.

4) Convert note to index

The overall score is then converted into a reparability index on a scale of 1 to 10. The manufacturer must isolate the colour pictogram corresponding to its score

5) Communicate the index

The producer must communicate the reparability index to distributors and must also make visible the information used to establish this calculation. The index must be displayed in accordance with the recommendations specified in the relevant regulations.

Who calculates the reparability index?

In France, the reparability index is self-reporting. This means that it is calculated by the producers themselves using the calculation matrices provided by French regulations.

In some cases, producers use independent third parties to calculate or verify their index for greater impartiality.

It should be noted that manufacturers are required to make available all the information used to define their indexes, so that anyone can check the accuracy of the information.

In the event of error or fraud, producers could be charged with misleading communication.

Which products are covered by the reparability index?

As specified in the AGEC law, the list of products covered by the French reparability index will be specified by decree. It currently covers 9 different product categories, divided between household appliances, digital cameras and tools;

- Corded, cordless and robot vacuum cleaners

- Laptop computer

- Front-mounted washing machine (porthole)

- Top loading washing machine

- Dishwashers

- High-pressure cleaner

- Smartphone

- Television

- Electric lawnmower

For smartphones, a European reparability index is being created. Unfortunately, these two indices are not based on the same calculation method.

What are the limits of the reparability index?

.Many entities have pointed out the limitations of the reparability index. As experts in the field of reparability and sustainability, our company, Ethikis, was one of the groups involved in the construction of the reparability index.

Right from the start of the consultation process, we raised three points of criticism.

The notion of self-declaration

History has taught us that some companies can be resourceful in circumventing regulations. Even if 99.9% of producers calculate their indexes sincerely, the risk of a DieselGate-style scandal remains high. The DGCCRF has the necessary authority to check the veracity of the scores communicated by producers and to impose penalties in the event of fraud.

However, the financial penalties remain low in relation to the stakes.

Lack of weighting of criteria in the index

An electric lawnmower rated 8.7/10 but with no spare parts available. This seems completely illogical, but above all it’s a far cry from the objectives of the index. To counter this problem, the French Ministry for Ecological Transition recently announced an update of the criteria incorporating exclusion scores and weighting mechanisms: essential!

The risk of collision with reliability

Above all, consumers want products that are reliable and won’t break down. Encouraging repairable products is an excellent thing, but we must be careful not to steer consumers towards less durable products.